wire edm machine is an electro process

Electro-discharge erosion is another name for this. The Lazarenkos two Soviet scientists who worked on the development of modern wire EDM and small hole EDM created a.

Wire Cut Edm Process 2 Download Scientific Diagram

The Wire EDM Spark EDM Process.

. Overview of EDM Cutting. The Wire EDM Spark EDM Process. The Wire EDM Spark EDM Process.

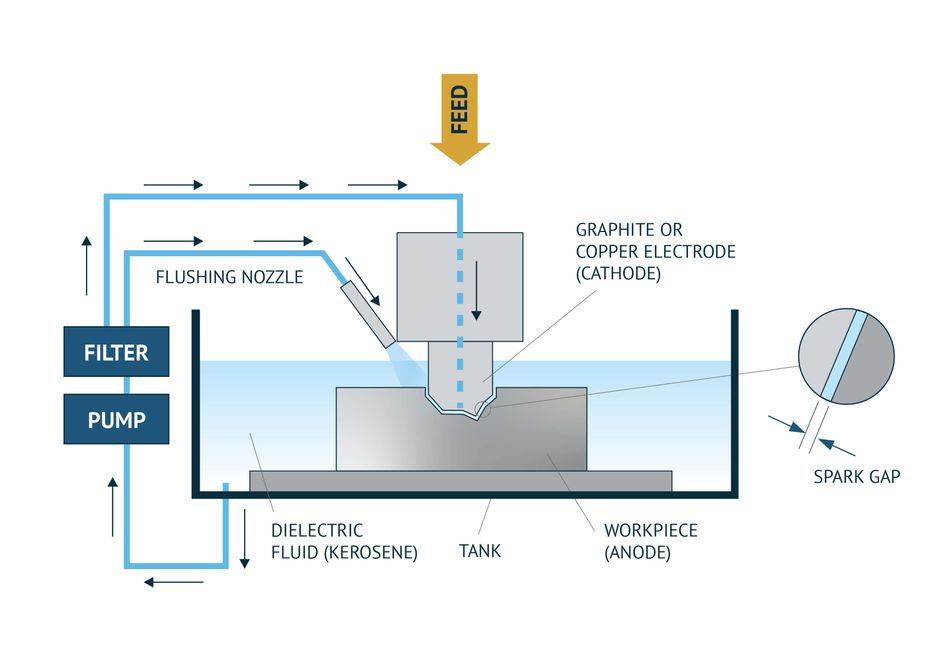

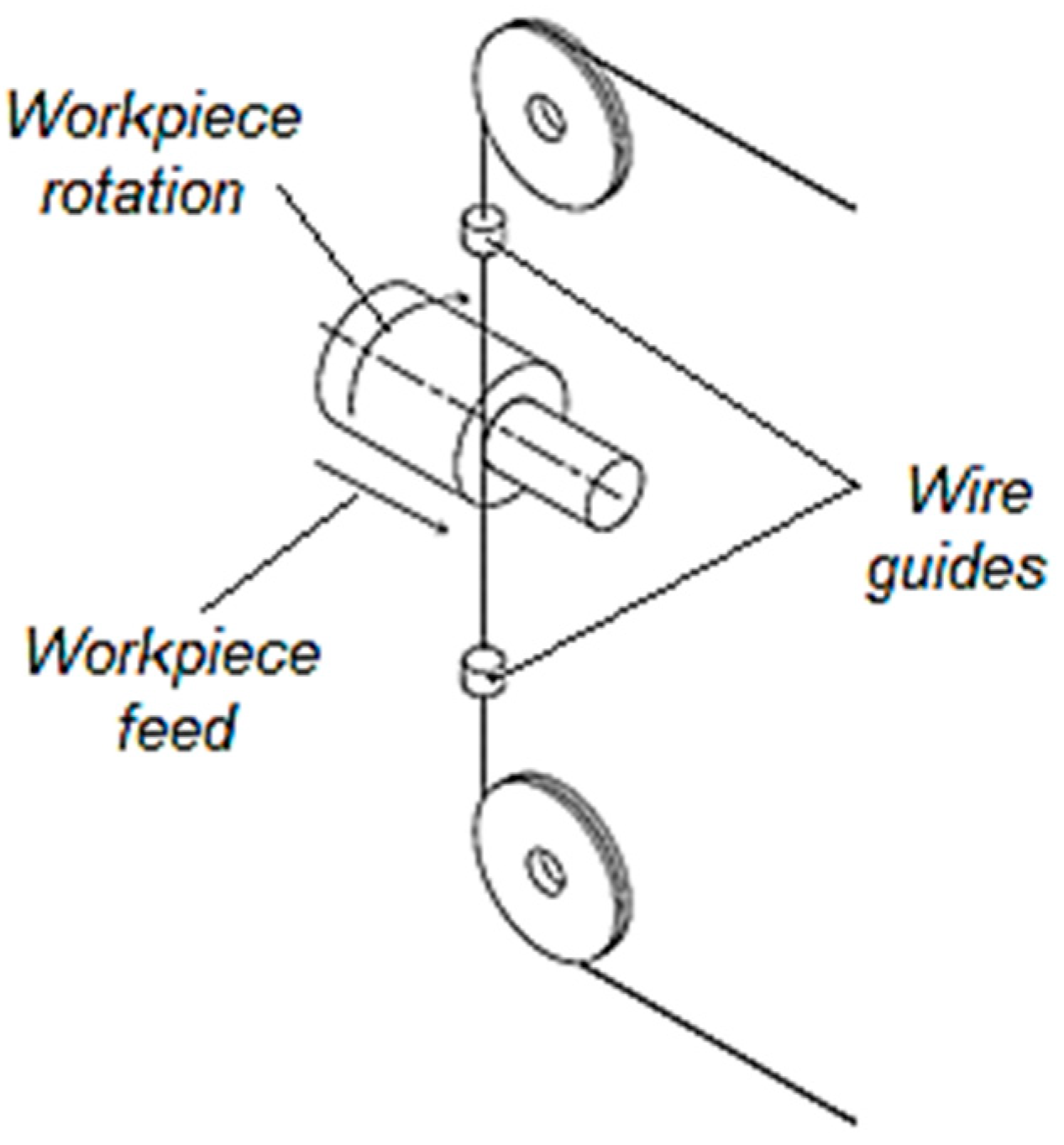

Wire EDM machines can also move along five axes including being inclined to create tapered effects on the metal and offering more degrees of freedom. Electrical discharge machines work on the principle of material removal using a series of electric Spark discharges occurring between the electrode tool and the. Die sinking EDM also known as Ram sinker traditional volume or cavity-type EDM is the best Electro Discharge Machining for creating parts with complex cavities.

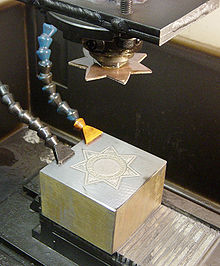

The wire EDM process uses an electrical current to melt a thin metal wire which is then used to cut through a workpiece. Wire EDM Machining also known as Spark EDM is an electro thermal production process in which a thin single-strand metal wire usually. EDM Electro Erosion is a machining process that uses a discharge electrode EDM electrode with a specific geometry.

Sammlite CNC EDM Manufacturer. Wire EDM machining is an electro thermal process which utilizes a thin metal wire in a bath of with de-ionized water which is used to conduct electricity. Also known as spark machining cutting EDM cutting is a cutting process that involves the use of electrical discharge to slice through metal workpieces.

This process allows the wire to cut. A major advantage of wire EDM over conventional EDM is that the continuous supply of wire minimizes the wear that occurs with a fixed electrode. EDM stands for Electrical Discharge.

This process is typically used for hard metals that are. The EDM wire cutting machine tool mainly processes flat workpieces. A wire EDM machine can consume a lot.

The movement of wire EDM is to move the workpiece and EDM is processed by moving the. The EDM wire cutting machine tool mainly processes flat workpieces. Faculty Web Server Directory Listing.

Wire EDM Machining also known as Spark EDM is an electro thermal production process in which a thin single-strand metal wire usually brass in. A wire EDM machine works in a similar way to a cheese cutter or a bandsaw cutting wood although the wire moves rather than. Wire Electrical Discharge Machining or Wire EDM is an electro thermal production process where a thin single strand metal wire along with de-ionised water used to conduct electricity allows.

This process allows the wire to cut.

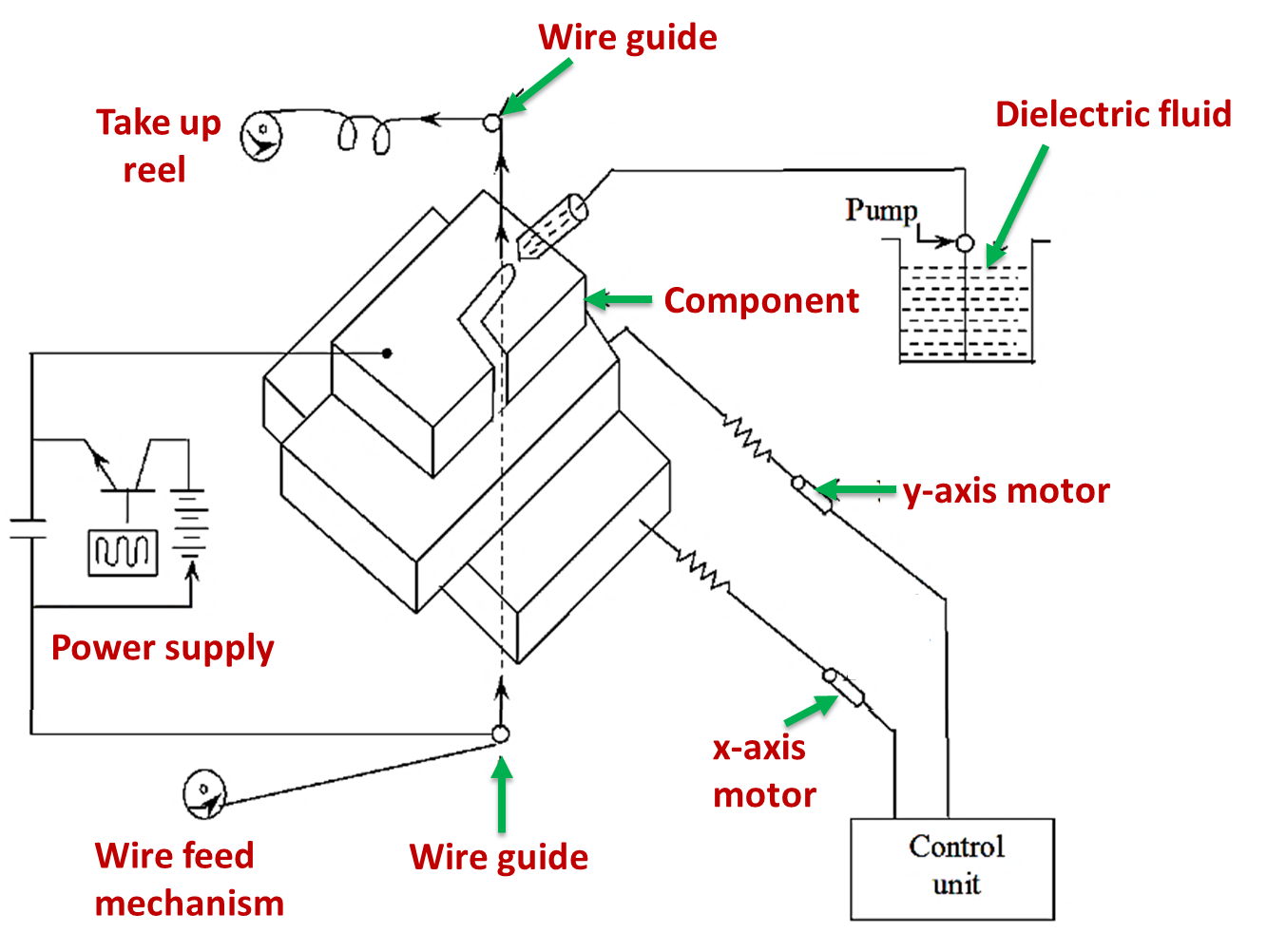

Schematic Diagram Of A Wire Edm Machine Download Scientific Diagram

Wire Electric Discharge Machining Wire Edm Youtube

Why Work Piece Is Always Made Anode In Edm Electric Discharge Machining Process Quora

The Benefits Of Using A Wire Edm Inverse

Wire Edm Guide To Edm Wirecut Machine Process Uses Fine Metalworking

Electrical Discharge Machining Wire Edm Edm Machining

What Is Wire Edm Electrical Discharge Machining Xact

Analysis And Optimization Of Wire Electro Discharge Machining Process Parameters For The Efficient Cutting Of Aluminum 5454 Alloy Sciencedirect

Electrical Discharge Machining Wikipedia

Electrical Discharge Machining Edm Everything You Need To Know

Line Diagram Of Wire Cut Edm Process Download Scientific Diagram

Wire Edm Find Suppliers Processes Material

Electrical Discharge Machining Wikipedia

Machines Free Full Text Wire Electrical Discharge Machining A Review Html

What Is Wire Edm Wire Electric Discharge Machining Process Diagram Construction Applications Electricalworkbook

Review On Wire Electrical Discharge Machining Wedm Of Aluminum Matrix Composites Semantic Scholar

The Hidden Cost Of Edm Wire Consumption Modern Machine Shop

Edm 101 Electrical Discharge Machining Basics Engineering Com

Electrical Discharge Machining An Overview Sciencedirect Topics